|

|

|

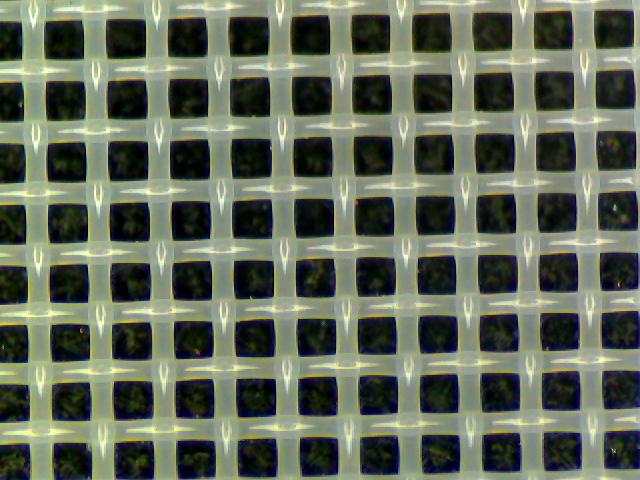

ECONOMY |

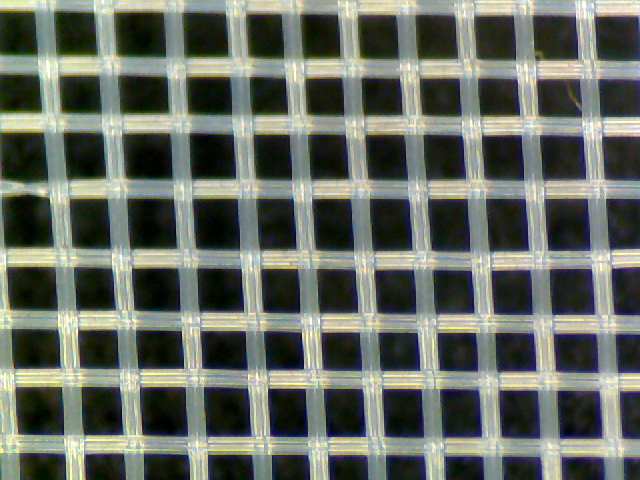

HIGH QUALITY |

||

|

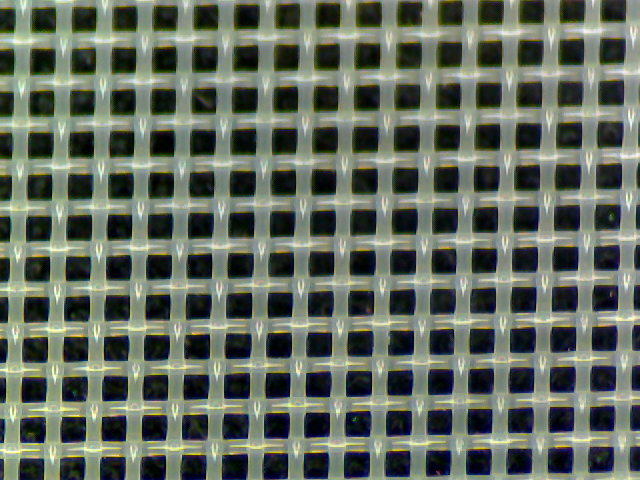

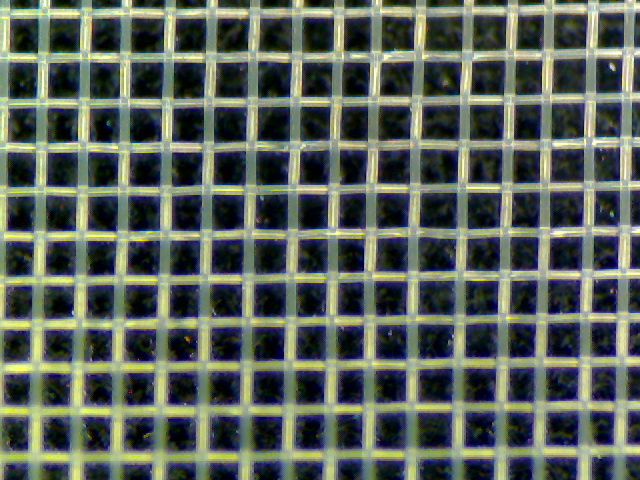

TYPE |

MESH |

|

|

||

|

|

|

|

|

||

|

|

MICRON RANGE |

||||

|

MESH |

40 |

X |

240 -260 |

||

|

MESH |

80 |

195-220 |

190-195 |

||

|

MESH |

120 |

125-140 |

129 - 135 |

||

|

MESH |

200 |

X |

63 -66 |

||

|

MESH |

400 |

X |

51 - 60 |

||

|

MESH |

600 |

X |

44 -45 |

||

|

ACCURACY |

Deviation + 20 |

Deviation + 5 |

|||

|

CHEMICAL RESISTANT |

NO |

YES |

|||

|

FABRIC |

NYLON |

POLYESTER |

|||

|

CONFORMS |

EN204/D3 STANDARD |

||||

|

KIND OF TEST |

|

UNIT |

Test Method Reference |

170(Gloss) |

Tolerance |

|

GRAMMAGE |

|

Gsm |

T-410 om-93 |

170 |

Less than 130±4%,130 and above ±2.5% |

|

BULK |

|

Cc/Gm |

T-411 om-89 |

0.83 |

±0.03 |

|

BENDING STIFFNESS |

MD |

Mn |

T-836 pm-95 |

360 |

Min. |

|

10mm, 300 angle |

CD |

Mn |

|

210 |

Min. |

|

BREAKING LENGTH |

MD |

Mts. |

T-494 om-88 |

4500 |

±500 |

|

|

CD |

Mts. |

|

2000 |

±500 |

|

ISO BRIGHTNESS |

|

% |

T-452 om-92 |

88 |

±1 |

|

ISO GLOSS AT 75° |

|

% |

T-480 om-92 |

75 |

±5 |

|

PARKER PRINT SURF |

T/B |

µ |

T-555 pm-94 |

0.90 |

Max. |

|

IGT (MVO) |

MD |

Cm/Sec |

T-514 cm-92 |

110 |

Min. |

|

SURFACE pH |

T/B |

T-529 om-88 |

7 - 8 |

- |

|

Inspection |

Inspection Method |

Value |

|

Solid Content |

BPL Method |

> 54.5 wt. % |

|

Viscosity at 25 °C |

BPL method |

3,500 – 4,500 cps |

|

Ph |

BPL method |

4.0-6.0 |

|

Density at 20 °C |

BPL method |

approx. 1,07 g/cm³ |

|

Minimum film forming temperature |

BPL method |

0 ℃ |

|

Frost resistance |

BPL method |

protect from freezing |

|

predominant particle size |

|

approx. 1,000 nm |

|

Protective colloid / emulsifier system |

|

PVOH |

|

Filler and pigment compatibility |

|

very good |

|

Appearance |

|

clear, glossy |

|

Surface |

|

Slight Dry Tack |

|

Tensile strength |

|

approx. 5 N/mm2 |

|

Elongation at break |

|

approx. 600 % |

|

Glass transition temperature |

|

approx. 0±2 °C |

|

Sr |

Test Parameters |

Result |

Test Method |

|

1 |

Oil content, % by mass |

Absent |

AOAC 920.85 |

|

2 |

Silicon Migration test( with Filtration) |

Nil |

In House. |

© 2017 Paperpaintstrainer.com. All Rights Reserved | Design by Techpex India